Chemical milling

Chemical milling

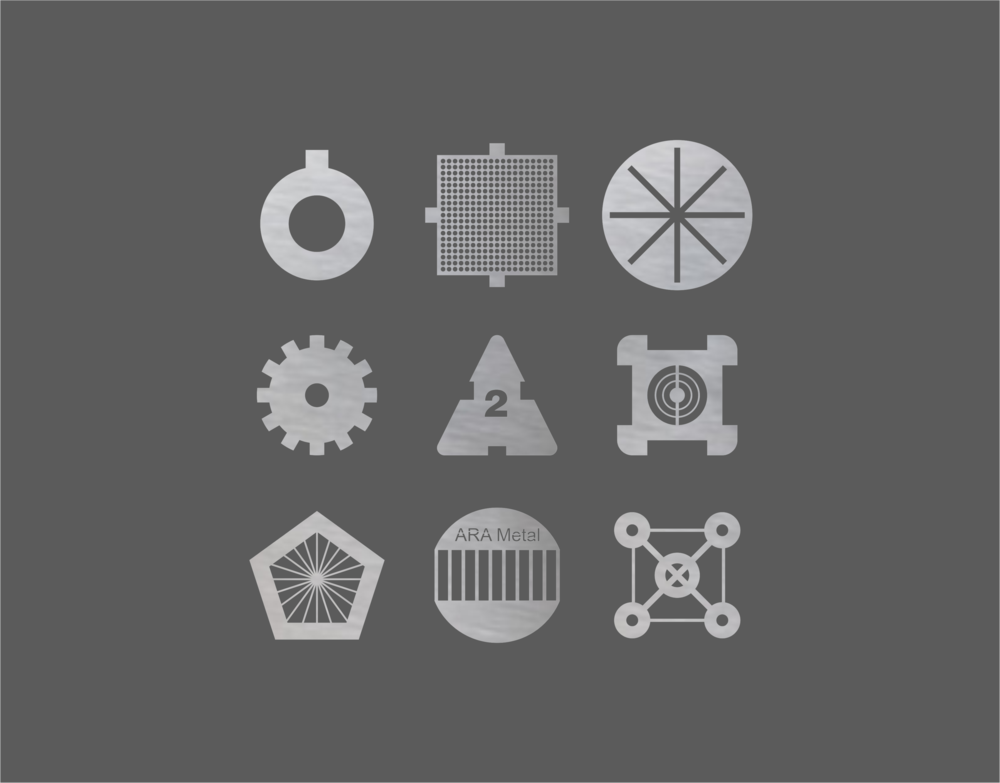

Chemical milling is an advantageous method for manufacturing mechanical components in thin sheet metal. Plate thicknesses from 0.05 mm and up to approx. 2 mm.

The shape of the finished item is photochemically transferred to the material via a UV stencil, so there are no tool costs. The etching takes place on both sides and the finished result appears completely without burrs and stresses.

It is possible to etch very fine details down to fractions of a millimeter. The finished items can be further machined such as bending or shaping.

Chemical milling is an optimal method for the production of both prototypes and large series of fine items with great detail. In some cases, chemical milling can also be an alternative to CNC cutting and punching.

ISO9001: 2015